Დაცვა თქვენი მაशინები FANTECH-ის საფირმო ბურთულების საფირმოები , შემდგომიანი დარგვილის შემცირებისა და კანონის გადაწყვეტილობის პრევენციისთვის. სიზუსტით ბალანსირებული კომპონენტები უზრუნველყოფენ გარკვეული მოქმედებას, Nawt მაღალი სიჩქარის შემთხვევაშიც. ეს პულები საშუალებას ძალენ ენერგიის ეფექტურობის გაუმჯობესებას და შაბათის სისტემებზე მოქმედი დახარჯების შემცირებას. იდეალურია გარეგნული წნევის მარტივი დაჭერისა, მეტალურგიული გრინდინგისა და ზღვის ფორმირებისა. გაუმჯობესების შესახებ თქვენი მართვა და მასალების შესადარებლად ინჟინირებული აბრაზივები.

FANTECH’s კერამიკის სანდინგის ბელტები გამოსახატავად მუშაობს მაღალი მუშაობის მასალებზე, როგორიცაა კომპოზიტები ან აეროსპაციური კომპონენტები. მიკრო-სტრუქტურიზებული კერამიკის აბრაზიურები შემცირებს სიგრძეს, რაც არადამარტივებს ზედაპირების გარდაქმნას სურاخზე ან მარბლზე. ეს ბელტები საშუალება აძლევს გამოყენებას wet/dry სანდინგის სისტემებში, რაც იხსნის მათ ავტომობილების ან კერამიკის წარმოებისთვის. გამოსახატავი პროდუქტივობა მიიღებთ split-proof joints და anti-static coatings-ის გამოყენებით.

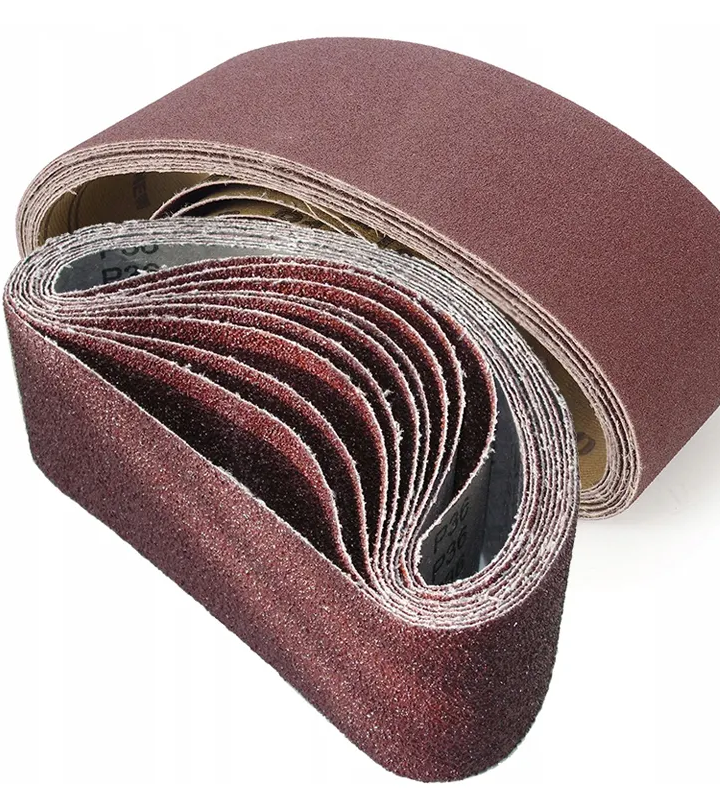

FANTECH’s zironcia sanding belts მოწოდებენ სწრაფ მასალის გამოკლებას სიმკვრივიან ხეზე ან დაფიქსირებულ მეტალებზე. თავისგან მრუდების გრანატები გრძელად შენარჩუნებულია მრუდის გამო უფრო გრძელი პროექტის დროის შემცირებისთვის 25%. გამოიყენეთ ღია-კოატი დიზაინი რეზინოვ ხეზე ან დაფიქსირებულ ზედაპირებზე. ეს ბელტები კარგად შეერთება პორტატიულ სანდერებთან სავარაუდო კონსტრუქციებისთვის ან განძის რეპარაციებისთვის.

Მაქსიმიზებთ ბელტის ცხოვრების განმავლობას FANTECH-ის გამოყენებით სანდინგის ბელტის შეკრულების ტეიპი რომ 脩修 torn edges ან შეერთოთ საკუთარი სიგრძეები. ეს მაღალი-განტოლებული ადჰეზივი მუშაობს fiberglass ან cloth ბელტებზე, რაც მინიმიზებს გადახარჯებს მაღალ მოცულობის ოპერაციებში. იდეალურია კონვეიერის ბელტის მაინტენანსისთვის ან custom-ზომის ბელტების შექმნისთვის niche მაशინებისთვის. შემცირებით გამოყენებით შეამცირეთ procurement ხარჯები 20–30%-ით.

FANTECH’s არაქსეული პროდუქტები გარეშე ხატული დამთავრებები სენსიტიურ მასალებზე, როგორც აკრილი ან გაფერადებული ქვაბი. ეს აბრაზივები შე祺ავად ნილონის თბას და მიღწევადი აბრაზივები რიცხვებისთვის ან ზღვარის მზადდებისთვის დაფარვისთვის. გამოიყენეთ ორბიტალური სანდერებით სტainless steel-ზე ან დეკორაციულ სურათზე მირორებული დამთავრებებისთვის. იდეალურია ელექტრონიკის შემსრულებლებისთვის ან ლუქსის მебლის შემცველებისთვის.

QINGDAO FANTECH ABRASIVES CO., LTD, არის პროფესიონალური კომპანია მიწოვრების მწარმოებაში და ექსპორტში.

Ჩვენი ძირითადი პროდუქტები 娷ებს ჭრის და გადაჭრის წრეებს, სანდინგ როლებს, სანდინგ ზოლებს, რეზინის თბა დისკებს, ფლეპ დისკებს, ფლეპ წრეებს, მინი ფლეპ დისკებს, სწრაფი შეცვლადი დისკებს, strip-it პროდუქტებს, non-woven პროდუქტებს, დიამანტის პროდუქტებს და სხვა მიწოვრების აксესუარებს. ჩვენ გთავაზობთ OEM და ODM სერვისებს. ჩვენი პროფესიონალური R&D გუნდით, შეგვიძლია გავufacture განსხვავებული პროდუქტები კლიენტების კონკრეტულ საჭიროების მიხედვით.

Ნაბვნვნვნ ეა თჱდლვეა ჟრანვკა ოპვკჟრთვ, ჱა ეა ჱაგყნსგა ოჲ-გლვეა ზთგჲრა.

Მდგრადი დიზაინი ამცირებს საჭიროებას ხშირად შეცვალოს.

Იდეალურია არარეგულარული და კონტურირებული ზედაპირებისთვის.

Აძლევს შესანიშნავ მასალის მოცილებას მინიმალური ძალისხმევით.

Არჩევა ბელტის ჭრის სამუშაოები ზომები დარგებულია პროექტის მასშტაბის მიხედვით: სულიერი ბელტები მრუდებისთვის, широкие - სიბრტყის ზედაპირებზე, როგორიცაა დეკები. ჩვენი აბრაზივები უზრუნველყოფს სMOOTH დამთავრებელ მუშაობას ხეზე, მეტალზე ან მარბლზე გარკვეული სანდინგის გარეშე.

Დიახ, პრემიუმი მშვილდოსანი დანის მკვეთრი მჭიდრო მჭიდი ინსტრუმენტები, რომლებიც დაყრდნობილია ზირკონია-ფოსტერი გრძელებით, წარმოადგენენ ზუსტი რänderები რკინაკის მეტალზე. გარღვევის გარეშე გამოიყენეთ მომდევნო წნევა და ერთforma მოძრაობა.

Აირჩიეთ მიკრო გრანული კერამიკული შლიფველი ტყე შექმნილია ხალხავით მასალებისთვის. გამოიყენეთ მიმართული წნევა და დარწმუნდით, რომ გრძელი sach თავის მახასიათებლებით შეესაბამება. იდეალურია სასურათო გლას ან სერამიკის პროექტებში.

Დარწმუნდით, რომ რუბანები არის გადასაწყვეტი სანდინგის ბელტის შეკრულების ტეიპი - აღდგენილი გრძელებით, რათა შემცირდეს გამომავალი. რეგულარული ხარისხი და განსაზღვრული შემოწმებები გრძელის ცხოვრებას გაიგზავნებიან, განსაკუთრებით მეტალის ან ხის გარღვევის დროს.

Გამოიყენეთ სპეციალიზებული შლისი, რათა ამოხსნათ ჩარჩოვნადობა ხის დაჭრვა, შლება და სანდინგის ტასი ფართებიდან. ეს შენახავს ქვედან მწვრთნელობას და გაფართოებს გამოყენებას სათავსო ან მебლის პროექტებისთვის.

Აბსოლუტურად. Zirconia ლასტები გამოჩნდნენ საუკეთესო როგორც სასაფრის დახრის დროს ლასტ-სანდრით, მითითებული ხანგრძლივობით წინააღმდეგ მძლავრ ხის გრანატებს. ისინი წარმართლებულია წარჩენის წინააღმდეგ და ეფექტურად მუშაობენ მაღალი სიჩქარის აპლიკაციებში.