Address demanding industrial tasks with FANTECH’s ceramic flap discs, engineered for extreme heat and pressure. These discs outperform traditional abrasives in longevity and cutting speed, ideal for welding seams and hardened steels. Their self-sharpening grains maintain sharpness, reducing frequent disc changes. A cost-effective alternative to grinding wheels, they excel in heavy fabrication and repair workshops.

Ceramic flap discs outperform traditional abrasives in high-temperature applications, ideal for hard alloys and repetitive tasks. Their micro-fracture design exposes fresh abrasive grains, reducing downtime for disc changes. For aluminum processing, pair with aluminum flap discs featuring anti-loading coatings to prevent material buildup. Ceramic options minimize heat generation, critical for aerospace or automotive components. Tip: Use 60-80 grit ceramic discs for weld blending and 120+ grit for final polishing.

For industrial buyers prioritizing surface finishing and material versatility, flap discs excel in blending, deburring, and preparing stainless steel surfaces without overheating. Unlike rigid grinding discs, which focus on aggressive material removal, flap discs offer controlled pressure and variable grit options. When working with stainless steel, choose stainless steel flap discs with non-ferrous abrasives to prevent contamination. Grinding discs suit heavy weld removal but risk gouging delicate surfaces. Tip: Pair flap discs with low-RPM angle grinders for extended tool life on stainless steel projects.

Consistency is crucial in industrial operations, and our flap discs deliver just that. Each disc is manufactured with precision to ensure that it performs the same way, every time. The stable structure and uniform abrasive distribution of our flap discs guarantee consistent material removal and surface finishing. Whether you're working on a single project or a large - scale production run, you can rely on our flap discs to provide reliable and consistent performance, helping you maintain the quality of your products.

We believe that high - quality products don't have to come with a high price tag. Our flap discs offer excellent value for money, combining top - notch quality with affordability. Through efficient manufacturing processes and strategic sourcing, we are able to keep costs down without sacrificing performance. Whether you're a small business looking to optimize your budget or a large enterprise in need of bulk purchases, our cost - effective flap discs are the perfect choice for you.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

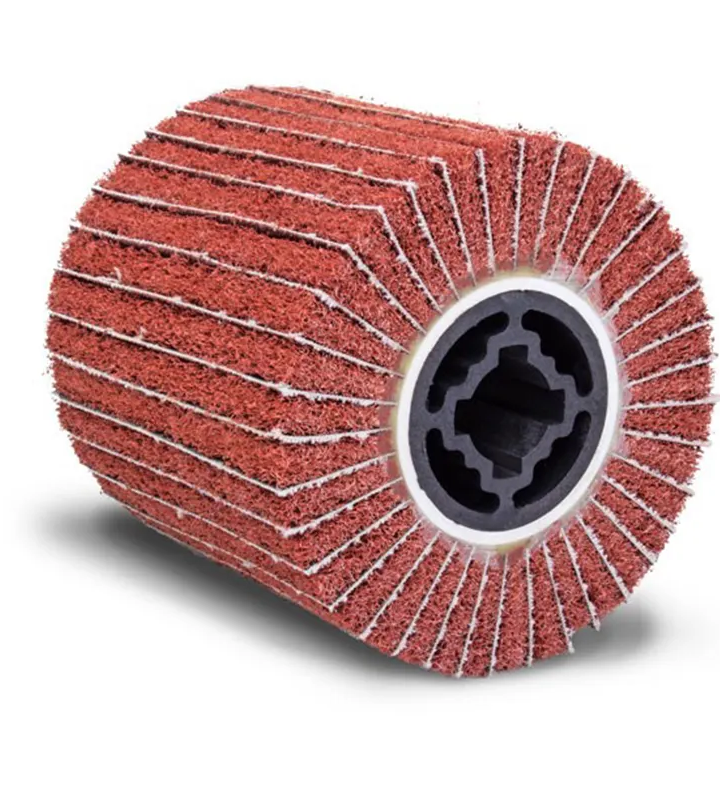

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Flap discs offer multi-surface blending with reduced heat generation, ideal for stainless steel and aluminum. Grinding discs focus on aggressive material removal but may leave deeper marks. Choose flap discs for precision finishing and MPA-certified durability.

MPA-certified flap discs ensure consistent performance on stainless steel and carbon steel. They meet rigorous safety standards, reduce workpiece contamination, and provide longer lifespan compared to non-certified abrasives.

Opt for aluminum flap discs or ceramic-coated abrasives for stainless steel. These minimize embedded contaminants and prevent discoloration. Pair with low-RPM angle grinders for optimal surface preparation

Use angle grinder flap discs with zirconia alumina for wood. They balance material removal and finish quality while preventing burn marks. Avoid traditional grinding wheels that may splinter grain patterns.

Diamond flap discs excel in concrete and hardened steel applications. Their segmented design maintains cutting efficiency while outperforming standard grinding wheels in longevity on abrasive surfaces.

Curved flap discs conform to complex contours in weld cleaning and deburring. Their flexible design outperforms rigid grinding discs for curved surfaces, reducing secondary finishing time by 30-40%.