Elevate woodworking projects with FANTECH’s angle grinder flap discs designed for smooth shaping and sanding. Unlike standard grinding discs, our sanding flap discs prevent gouging and overheating on delicate surfaces. Ideal for furniture makers and carpentry workshops, they enable rapid material removal while maintaining finish quality. Pair with low-speed grinders for optimal control on softwoods and hardwoods.

Quality is at the core of our flap discs. We source only the finest materials to ensure that each disc meets the highest industry standards. The abrasive flaps are bonded securely to the backing, preventing them from detaching during use and ensuring a smooth and safe operation. Our commitment to quality control means that every flap disc leaving our facility is rigorously tested for performance and durability. By choosing our premium - quality flap discs, you're investing in a product that will deliver superior results and enhance the quality of your work.

Stainless steel grinding flap discs combine grinding and finishing in one operation, using zirconia alumina abrasives for contamination-free results. Their hybrid design reduces tool changes when transitioning from weld removal to surface prep. For contoured surfaces, curved flap discs with flexible backing plates adapt to complex geometries in pipe fabrication. Tip: Match disc curvature radius (5mm-15mm) to workpiece profiles for optimal contact.

Our flap discs are designed to meet the demands of a wide range of applications. From deburring and shaping to polishing and finishing, these discs offer versatility like no other. Available in various grits and sizes, they can handle both light - duty and heavy - duty tasks with ease. The durable construction of our flap discs allows them to withstand high - speed operations, providing you with a tool that can keep up with the pace of your production line. Discover how our flap discs can be the solution for all your surface - treatment needs.

Convert standard angle grinders into woodworking tools with flap discs for wood, featuring coarse grits (24-40) for rapid stock removal without tear-out. For aluminum machining, best flap discs for aluminum utilize specialty coatings that resist "gumming up" – a common pain point in CNC maintenance. Use T27 depressed-center discs for flat surfaces and T29 conical designs for edge work. Tip: Maintain 8,000-10,000 RPM for wood and 6,500 RPM for non-ferrous metals.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

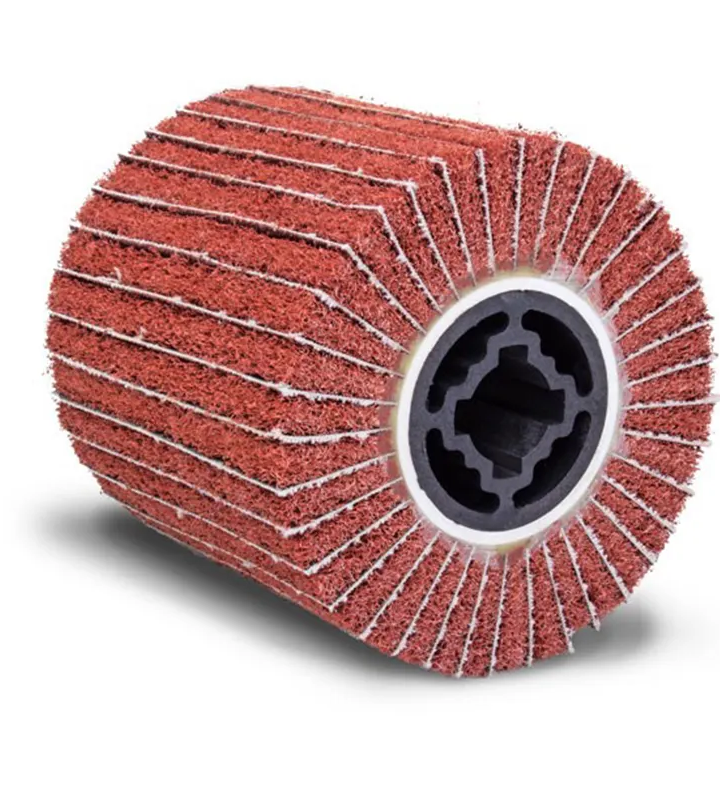

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Flap discs offer multi-surface blending with reduced heat generation, ideal for stainless steel and aluminum. Grinding discs focus on aggressive material removal but may leave deeper marks. Choose flap discs for precision finishing and MPA-certified durability.

MPA-certified flap discs ensure consistent performance on stainless steel and carbon steel. They meet rigorous safety standards, reduce workpiece contamination, and provide longer lifespan compared to non-certified abrasives.

Opt for aluminum flap discs or ceramic-coated abrasives for stainless steel. These minimize embedded contaminants and prevent discoloration. Pair with low-RPM angle grinders for optimal surface preparation

Use angle grinder flap discs with zirconia alumina for wood. They balance material removal and finish quality while preventing burn marks. Avoid traditional grinding wheels that may splinter grain patterns.

Diamond flap discs excel in concrete and hardened steel applications. Their segmented design maintains cutting efficiency while outperforming standard grinding wheels in longevity on abrasive surfaces.

Curved flap discs conform to complex contours in weld cleaning and deburring. Their flexible design outperforms rigid grinding discs for curved surfaces, reducing secondary finishing time by 30-40%.