Designed for fast-cutting abrasive discs, FANTECH’s ultra-thin options slice through metal sheets, pipes, and bolts with minimal sparking. The diamond abrasive disc variants excel in cutting hardened steel and concrete, offering 2x longer lifespan vs. standard discs. Lightweight and compatible with angle grinders, they enhance maneuverability in tight spaces. Our noise-reducing technology ensures quieter operation, meeting workplace safety regulations. Ideal for construction and fabrication, these discs reduce material waste and boost cutting accuracy.

In the era of modern manufacturing, innovation is crucial. Our abrasives discs incorporate the latest technological advancements. The unique design features enhance the disc's grip and stability during operation, resulting in more accurate cuts and finishes. These innovative discs are also environmentally friendly, with materials that meet strict industry standards. Stay ahead in the market by choosing our innovative abrasives discs for your manufacturing needs.

Industrial operations demand robust and efficient tools, and our abrasives discs fit the bill perfectly. They are ideal for applications such as deburring, shaping, and finishing in large - scale manufacturing. The discs' high - speed performance allows for quick processing, saving valuable time on the production line. Moreover, their compatibility with a variety of machines makes them a convenient choice for different production setups. Experience the power of our abrasives discs and transform your industrial processes.

Our diamond abrasive disc range utilizes electroplated monocrystalline diamonds for cutting granite, terrazzo, and reinforced concrete. The segmented rim design optimizes cooling during wet/dry operation on high-RPM grinders. Contractors appreciate the 2x faster cutting speed over traditional discs in roadwork and tile installation projects.

Certified eco-friendly abrasive discs incorporate 60% recycled abrasives without sacrificing cutting aggression. The water-resistant latex backing suits marine applications where chemical runoff must be controlled. Shipyards and recycling plants achieve OSHA-compliant surface prep while reducing landfill contributions from spent discs.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

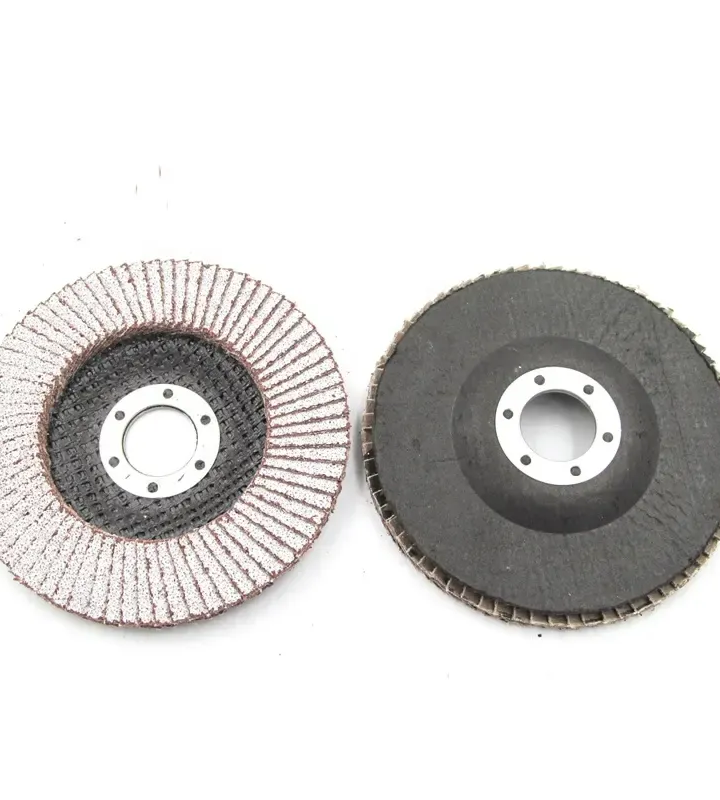

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

FANTECH offers aggressive abrasive discs designed for angle grinders, delivering fast material removal and durability. Our discs minimize vibration, ensuring precise control on metal, wood, or composite surfaces.

Use our low-vibration abrasive discs for wood, engineered to reduce chatter and prevent surface burns. These discs provide consistent pressure distribution for flawless sanding and finishing.

Yes! FANTECH’s eco-friendly abrasive discs for metal feature recyclable materials and reduced dust emission. They maintain high cutting efficiency while aligning with sustainability goals.

Opt for our fast-cutting abrasive discs with reinforced fiberglass backing. They excel in slicing through thick metals, offering extended lifespan and heat resistance.

Absolutely. FANTECH’s diamond abrasive discs handle granite, ceramics, and hardened steel. Their non-clogging design ensures uninterrupted performance for industrial applications.

Our non-clogging abrasive discs utilize advanced coating technology to resist material buildup. Perfect for paint removal or rust cleanup, they maintain efficiency without frequent replacements.