FANTECH specializes in manufacturing abrasive flap wheels engineered to deliver unmatched efficiency in metalworking, wood finishing, and surface preparation. Our aluminum oxide flap wheels are crafted with premium-grade materials, offering extended durability and consistent performance for aggressive material removal on stainless steel, aluminum, and alloys. Ideal for bench grinder and die grinder applications, these wheels ensure minimal vibration and heat generation, reducing workpiece damage.

For intricate projects, our ceramic flap wheels provide superior edge retention and cooler operation, making them perfect for high-stress industrial environments. Customizable grit sizes (coarse to fine) accommodate tasks ranging from heavy-duty deburring to fine polishing. Compatible with drill sanding tools and angle grinders, FANTECH’s flap wheels are versatile across automotive, aerospace, and fabrication sectors.

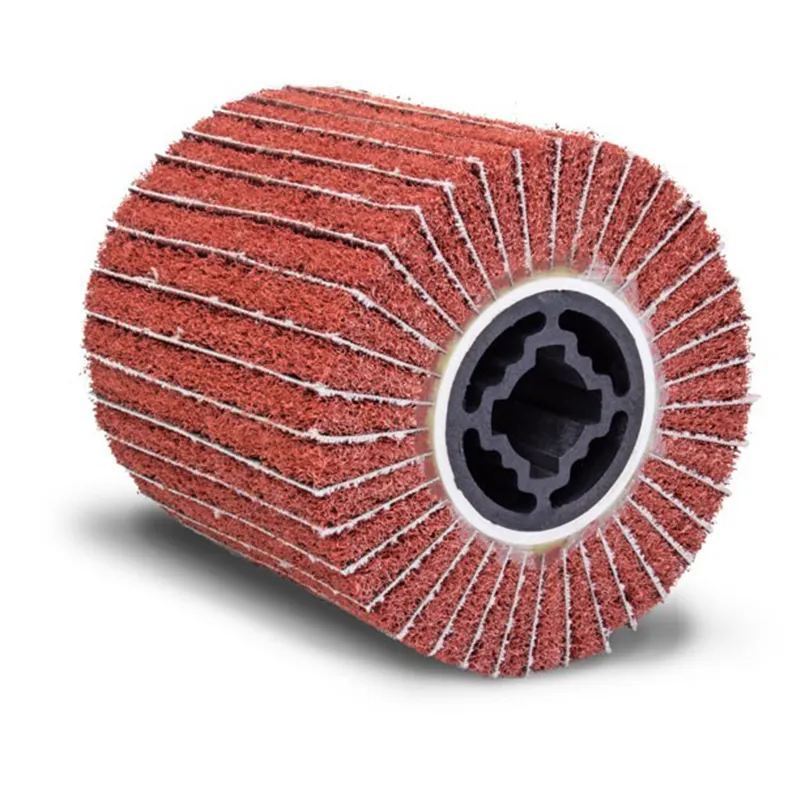

We also offer non-woven flap wheels for delicate surfaces and diamond flap wheels for ultra-hard materials. Our solutions prioritize user safety with ergonomic designs and ISO-certified manufacturing. Partner with FANTECH to optimize productivity, reduce downtime, and achieve flawless finishes. Contact us for tailored flap wheel configurations matching your equipment specs and operational needs.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Opt for high-speed aluminum oxide flap wheels designed for angle grinders, ensuring compatibility with curved surfaces and aggressive material removal. Our durable construction minimizes vibration, ideal for stainless steel, wood, or alloy polishing.

Ceramic abrasive grains in flap wheels offer extended lifespan and cooler grinding, reducing workpiece burn. They excel in high-pressure tasks like weld blending or deburring hardened metals, outperforming traditional aluminum oxide options.

Yes, compact shank-mounted flap wheels (e.g., 1/4" shaft) provide controlled polishing in tight spaces. Pair with fine-grit non-woven abrasives for smooth finishes on automotive parts, molds, or intricate metalwork.

Electroplated diamond flap wheels deliver unmatched durability on ceramics, stone, or glass. Their consistent cutting action avoids uneven wear, making them cost-effective for industrial stone shaping or concrete surface prep.

Absolutely. Low-density non-woven flap wheels gently clean and finish soft metals or plastics without scratching. Use with lighter pressure for paint stripping, rust removal, or final satin finishes on sensitive substrates.

Multi-layered aluminum oxide abrasive flaps balance affordability and performance, ideal for general-purpose grinding. They resist loading during woodworking or metal fabrication, reducing downtime for wheel changes.