When selecting between flap discs and grinding discs, prioritize versatility and precision. Flap discs excel in blending, deburring, and finishing surfaces, reducing the need for multiple tools. Grinding discs focus on aggressive material removal but lack the finesse for polished outcomes. FANTECH’s flap discs feature durable abrasives for consistent performance on stainless steel, aluminum, and wood, ensuring smoother finishes and extended tool life. Ideal for metal fabrication and automotive industries, our products minimize downtime and enhance workflow efficiency. Choose FANTECH for adaptable solutions that balance speed and surface quality.

We understand that every business has unique requirements. That's why we offer customizable flap discs. Our professional R & D team works closely with you to understand your specific needs and develop flap discs that are tailored to your operations. Whether you need a specific grit combination, a custom size, or a unique design, we can bring your ideas to life. With our OEM and ODM services, you can have flap discs that are perfectly suited to your production processes, giving you a competitive edge in the market.

Strip-it flap discs with multi-layered abrasive flaps reduce coating removal costs by 40% compared to traditional sanding. Integrate with quick change flap disc systems using auto-lock hubs to minimize machine downtime in high-volume production. Tip: Calculate cost-per-square-meter using disc lifespan data from technical datasheets.

In the era of modern manufacturing, innovation is essential. Our flap discs incorporate the latest technological advancements to offer improved performance and functionality. New bonding techniques enhance the disc's strength and stability, while advanced abrasive materials provide better cutting efficiency. These innovative features not only make our flap discs more effective but also contribute to a more sustainable and environmentally friendly manufacturing process. Stay ahead of the competition with our innovative flap discs.

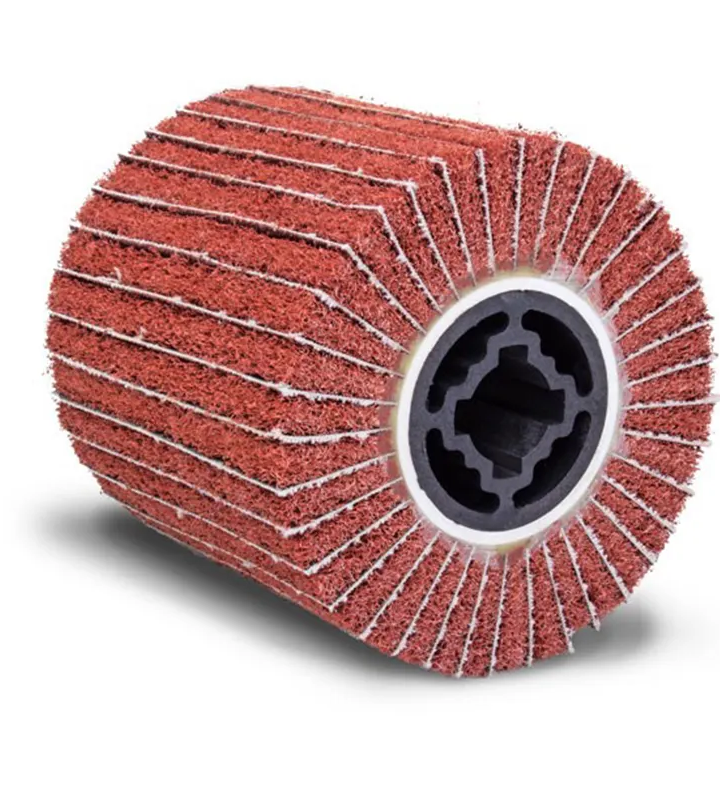

Non-woven flap discs with nylon fiber backing excel in final finishing of soft metals and composites. Their 3D abrasive structure cleans surfaces without scratching – critical for architectural aluminum or medical equipment. Combine with sanding flap discs for progressive grit transitions (P80-P220) in automotive refinishing. Tip: Use random orbital motion with 15° disc angle for swirl-free finishes.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Flap discs offer multi-surface blending with reduced heat generation, ideal for stainless steel and aluminum. Grinding discs focus on aggressive material removal but may leave deeper marks. Choose flap discs for precision finishing and MPA-certified durability.

MPA-certified flap discs ensure consistent performance on stainless steel and carbon steel. They meet rigorous safety standards, reduce workpiece contamination, and provide longer lifespan compared to non-certified abrasives.

Opt for aluminum flap discs or ceramic-coated abrasives for stainless steel. These minimize embedded contaminants and prevent discoloration. Pair with low-RPM angle grinders for optimal surface preparation

Use angle grinder flap discs with zirconia alumina for wood. They balance material removal and finish quality while preventing burn marks. Avoid traditional grinding wheels that may splinter grain patterns.

Diamond flap discs excel in concrete and hardened steel applications. Their segmented design maintains cutting efficiency while outperforming standard grinding wheels in longevity on abrasive surfaces.

Curved flap discs conform to complex contours in weld cleaning and deburring. Their flexible design outperforms rigid grinding discs for curved surfaces, reducing secondary finishing time by 30-40%.