FANTECH’s coated abrasive discs offer multi-stage grinding and finishing in one tool. The overlapping flaps adapt to contours, ideal for curved surfaces on metal or wood. The zirconia grains provide fast-cutting action, while the low-vibration design reduces operator fatigue. With a 20% longer lifespan than competitors, these discs are essential for maintenance, repair, and fabrication teams seeking efficiency.

In the competitive world of manufacturing, using top - tier abrasives discs can make all the difference. Our products are designed with the latest industry knowledge and expertise. The abrasive grains are evenly distributed, enabling uniform material removal and a superior finish. These discs are also highly resistant to heat and wear, minimizing the need for frequent replacements. By choosing our abrasives discs, you're investing in quality that will elevate the standard of your work and give you an edge over your competitors.

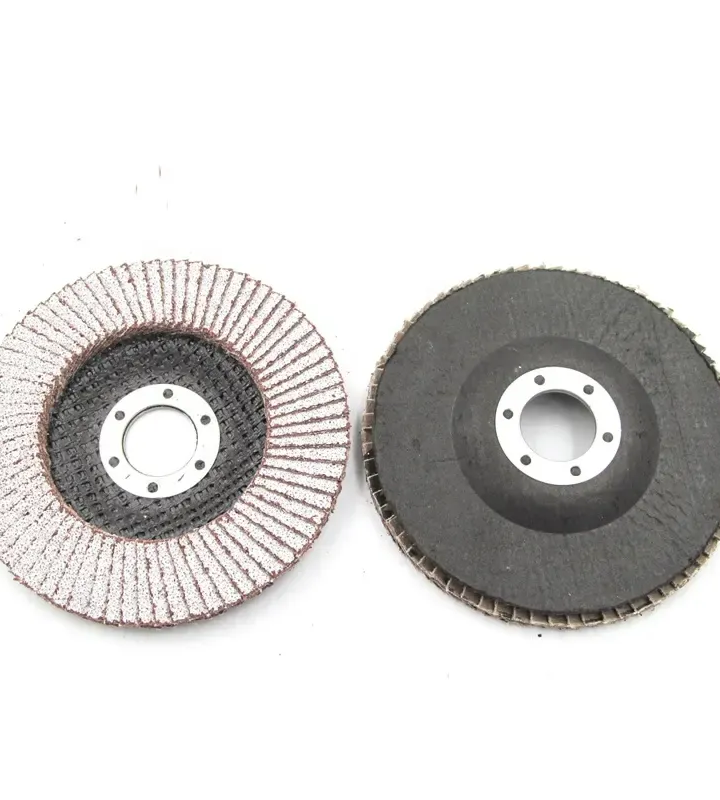

Hybrid fast-cutting abrasive disc designs combine zirconia alumina strips with overlapping flaps for seamless transitions between grinding and finishing. The tapered edge profile allows contouring on automotive body panels and stainless steel welds. Maintenance teams in manufacturing plants report 25% faster job completion versus conventional flap wheels.

FANTECH's non-clogging abrasive disc series features open-coat aluminum oxide grit that resists resin accumulation when sanding hardwood or MDF. The staggered perforation pattern enhances dust extraction, maintaining consistent performance on orbital sanders. Cabinet makers and furniture factories benefit from 40% longer lifespan and reduced downtime for disc changes.

At 1.0mm thickness, ultra-thin abrasive discs enable narrow kerf cuts in tight areas like engine compartments or electrical conduits. The fiberglass reinforcement prevents warping during side-loading tasks. HVAC technicians and metal fabricators value the reduced sparking and material waste in retrofit projects.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

FANTECH offers aggressive abrasive discs designed for angle grinders, delivering fast material removal and durability. Our discs minimize vibration, ensuring precise control on metal, wood, or composite surfaces.

Use our low-vibration abrasive discs for wood, engineered to reduce chatter and prevent surface burns. These discs provide consistent pressure distribution for flawless sanding and finishing.

Yes! FANTECH’s eco-friendly abrasive discs for metal feature recyclable materials and reduced dust emission. They maintain high cutting efficiency while aligning with sustainability goals.

Opt for our fast-cutting abrasive discs with reinforced fiberglass backing. They excel in slicing through thick metals, offering extended lifespan and heat resistance.

Absolutely. FANTECH’s diamond abrasive discs handle granite, ceramics, and hardened steel. Their non-clogging design ensures uninterrupted performance for industrial applications.

Our non-clogging abrasive discs utilize advanced coating technology to resist material buildup. Perfect for paint removal or rust cleanup, they maintain efficiency without frequent replacements.