FANTECH’s aggressive abrasive disc range tackles the toughest grinding tasks, from weld removal to surface leveling. The ceramic alumina grains stay sharp longer, reducing replacement frequency by 40%. Compatible with angle grinders, these discs feature a durable resin bond for high-pressure applications. The anti-shatter design enhances safety, while the smooth-finish capability eliminates secondary polishing steps. Trust our abrasives to maximize productivity in foundries, shipyards, and automotive repair.

At 1.0mm thickness, ultra-thin abrasive discs enable narrow kerf cuts in tight areas like engine compartments or electrical conduits. The fiberglass reinforcement prevents warping during side-loading tasks. HVAC technicians and metal fabricators value the reduced sparking and material waste in retrofit projects.

Reduce operator fatigue with low-vibration abrasive disc technology designed for handheld angle grinders. The specialized composite materials dampen oscillation by 30% compared to standard discs, enabling precise cuts on pipes, bolts, and sheet metal. This innovation is critical for automotive repair shops and construction teams requiring error-free results without compromising safety.

FANTECH's noise-reducing abrasive disc line uses viscoelastic damping layers to lower operational decibel levels by 15 dB. This is critical for renovation crews working in occupied spaces like hospitals or offices. The modified ceramic grain structure maintains cutting speed while meeting strict indoor air quality standards.

Our diamond abrasive disc range utilizes electroplated monocrystalline diamonds for cutting granite, terrazzo, and reinforced concrete. The segmented rim design optimizes cooling during wet/dry operation on high-RPM grinders. Contractors appreciate the 2x faster cutting speed over traditional discs in roadwork and tile installation projects.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

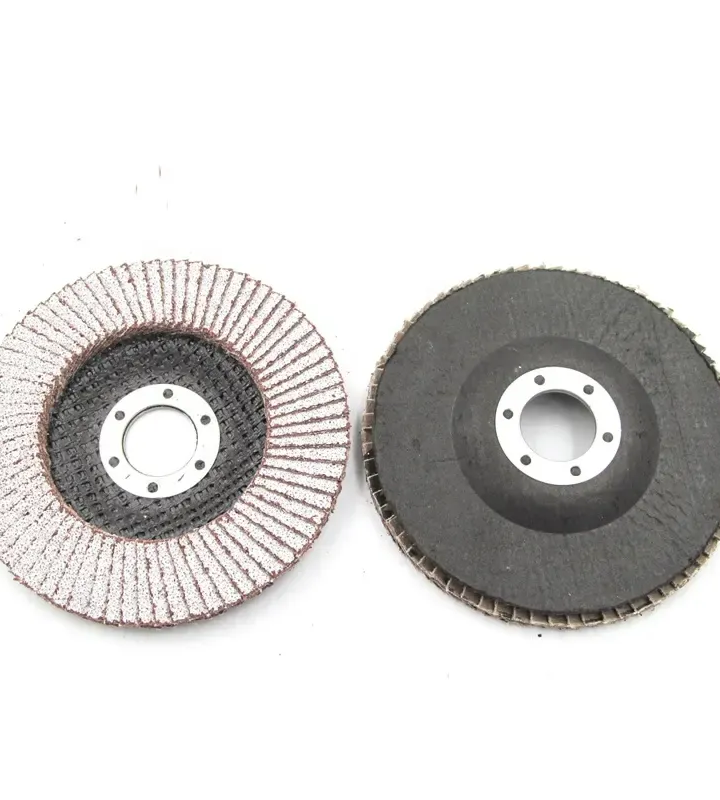

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

FANTECH offers aggressive abrasive discs designed for angle grinders, delivering fast material removal and durability. Our discs minimize vibration, ensuring precise control on metal, wood, or composite surfaces.

Use our low-vibration abrasive discs for wood, engineered to reduce chatter and prevent surface burns. These discs provide consistent pressure distribution for flawless sanding and finishing.

Yes! FANTECH’s eco-friendly abrasive discs for metal feature recyclable materials and reduced dust emission. They maintain high cutting efficiency while aligning with sustainability goals.

Opt for our fast-cutting abrasive discs with reinforced fiberglass backing. They excel in slicing through thick metals, offering extended lifespan and heat resistance.

Absolutely. FANTECH’s diamond abrasive discs handle granite, ceramics, and hardened steel. Their non-clogging design ensures uninterrupted performance for industrial applications.

Our non-clogging abrasive discs utilize advanced coating technology to resist material buildup. Perfect for paint removal or rust cleanup, they maintain efficiency without frequent replacements.