Maximize belt longevity with FANTECH’s sanding belt splicing tape, engineered to restore torn or worn abrasives. Heat-resistant adhesive ensures secure bonds, reducing material waste and operational interruptions. Compatible with fiberglass, zirconia, or ceramic belts, this solution suits workshops and production lines. Streamline maintenance routines while maintaining consistent performance across metal, glass, or marble applications. A cost-effective fix for extending the lifespan of high-value abrasives without compromising safety or efficiency.

Revitalize clogged belts using FANTECH’s sanding belt eraser, a reusable tool to clear resin or metal particles. Simply glide the eraser across the belt surface during operation to restore cutting efficiency. This eco-friendly solution extends belt life by 40%, reducing replacement costs for flooring contractors or metal workshops.

Industrial metal workshops rely on FANTECH’s stainless steel sanding belts to handle high-pressure grinding. These belts combine ceramic grains with flexible backings, eliminating scratch marks on stainless steel or alloy surfaces. Use coarse grits for weld removal and finer grits for polishing. Our belts withstand high RPMs on bench grinders, ensuring durability for knife sharpening or tool maintenance.

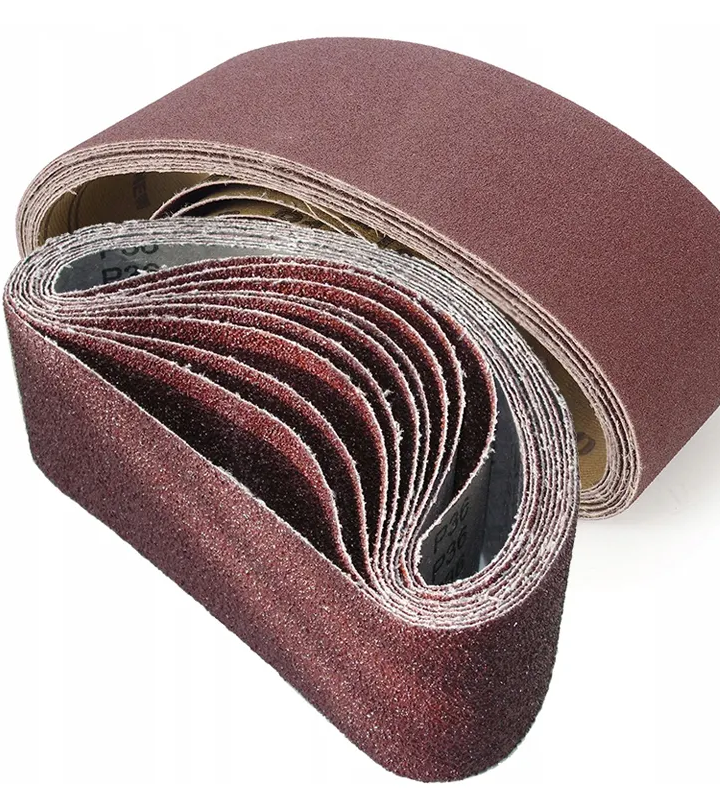

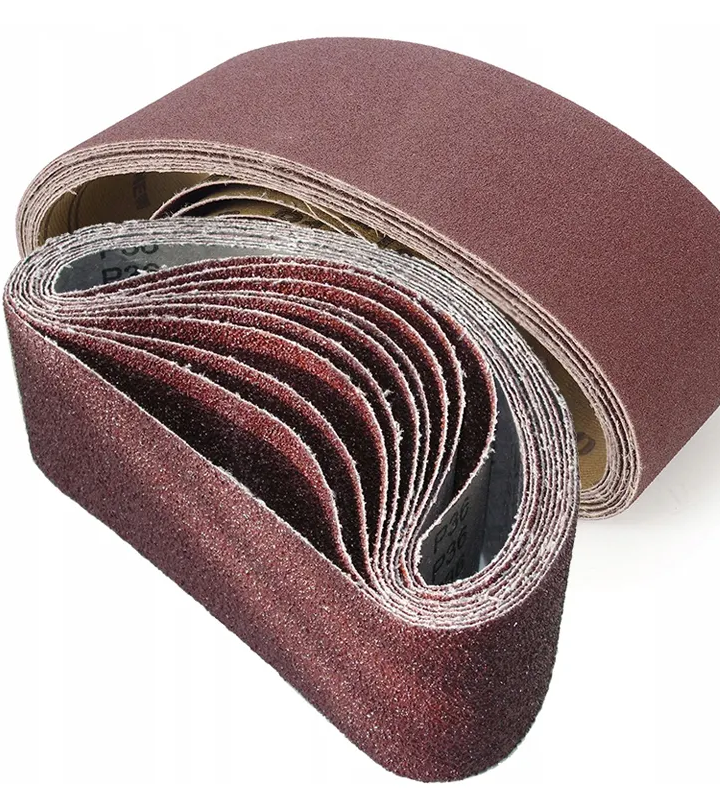

FANTECH’s zirconia sanding belts deliver rapid stock removal on dense woods or coated metals. The self-sharpening grains stay sharp longer than conventional belts, cutting project time by 25%. Use open-coat designs for resinous woods or painted surfaces. These belts pair well with portable sanders for on-site construction or shipyard repairs.

Upgrade equipment with FANTECH’s sanding belt pulleys engineered to prevent slippage under heavy loads. Anodized aluminum pulleys maintain alignment during prolonged use on wood or metal. Compatible with standard bench grinders, they reduce vibration for precise sharpening or deburring. Businesses report 15% higher operational efficiency due to reduced belt wear.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Select belt sanding sizes based on project scale: narrow belts for curves, wider ones for flat surfaces like decks. Our abrasives ensure smooth finishes on wood, metal, or marble without over-sanding.

Yes, premium belt sanding knife sharpener tools paired with zirconia-coated belts deliver precise edges on stainless steel. Avoid overheating by using moderate pressure and consistent motion.

Opt for fine-grit ceramics sanding belt designed for delicate materials. Use light pressure and keep the belt clean to minimize marks. Ideal for glass or ceramic restoration projects.

Ensure pulleys align with sanding belt splicing tape-repaired belts to reduce slippage. Regular lubrication and tension checks prolong belt life, especially for metal or wood grinding tasks.

Use a specialized eraser to remove buildup from wood grinding sanding belt surfaces. This preserves grit sharpness and extends usability for flooring or furniture projects.

Absolutely. Zirconia belts excel in sanding floorboards with a belt sander, offering durability against tough wood grains. They resist clogging and handle high-speed applications efficiently.