Tackle intricate tasks like mold cleaning or small-part deburring with FANTECH’s mini flap wheels. Compact 1"-2" designs fit into confined areas, offering maneuverability for electronics assembly or dental tool maintenance. The high-density abrasive flaps provide controlled material removal on plastics, soft metals, or composites. Compatible with rotary tools and pneumatic grinders, these wheels are a staple for aerospace and watchmaking industries. FANTECH’s lightweight construction reduces hand fatigue during prolonged use, while silicone-bonded grains ensure longevity. Perfect for artisans and engineers requiring millimeter-level accuracy.

For delicate tasks in tight spaces, FANTECH’s mini flap wheels (10-25mm) provide unmatched control. Compatible with drill sanding tools, they refine edges on pipes, gears, and electronic components. The zirconia alumina abrasive resheathes automatically, maintaining a sharp cutting surface. Lightweight and low-vibration, these wheels reduce operator fatigue during prolonged use. Applications include jewelry polishing, dental equipment, and automotive detailing. Customizable with 80-220 grits, they ensure a burr-free finish on soft metals and plastics.

As leading abrasive flap wheel suppliers, FANTECH provides tools engineered for intricate surfaces. Our diamond flap wheels excel in processing hardened metals and ceramics, delivering unmatched longevity. Suitable for curved or uneven geometries, they eliminate rework in tooling and mold maintenance. The non-loading abrasive design prevents clogging, maintaining efficiency in wet/dry conditions. Available in 1"-7" diameters, these wheels integrate seamlessly with angle grinders or bench tools. Trust FANTECH to deliver abrasives that balance speed, finish quality, and cost-effectiveness.

FANTECH offers aluminum oxide flap wheels designed for precision metal finishing and deburring. These wheels combine durability with aggressive material removal, ideal for stainless steel, alloys, and aluminum. Their heat-resistant design minimizes wear during prolonged use on die grinders, ensuring consistent performance in automotive and aerospace applications. Unlike standard abrasives, our flap wheels reduce vibration, enhancing operator comfort. Customizable grits (40-320) cater to coarse grinding or fine polishing. Partner with FANTECH for ISO-certified solutions that optimize productivity and reduce downtime.

Tailored for aluminum machining, FANTECH’s emery cloth flap wheels prevent galling and discoloration. The silicone-backed flaps resist loading when processing soft metals. Options include snap-on hubs for quick changes or threaded shafts for CNC machines. Industries like HVAC and electronics benefit from consistent finishes and reduced scrap rates. Request hybrid abrasives (aluminum oxide + silicon carbide) for mixed-material workpieces. Our R&D team collaborates with clients to develop application-specific solutions, ensuring compliance with ISO 9001 and IATF 16949.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

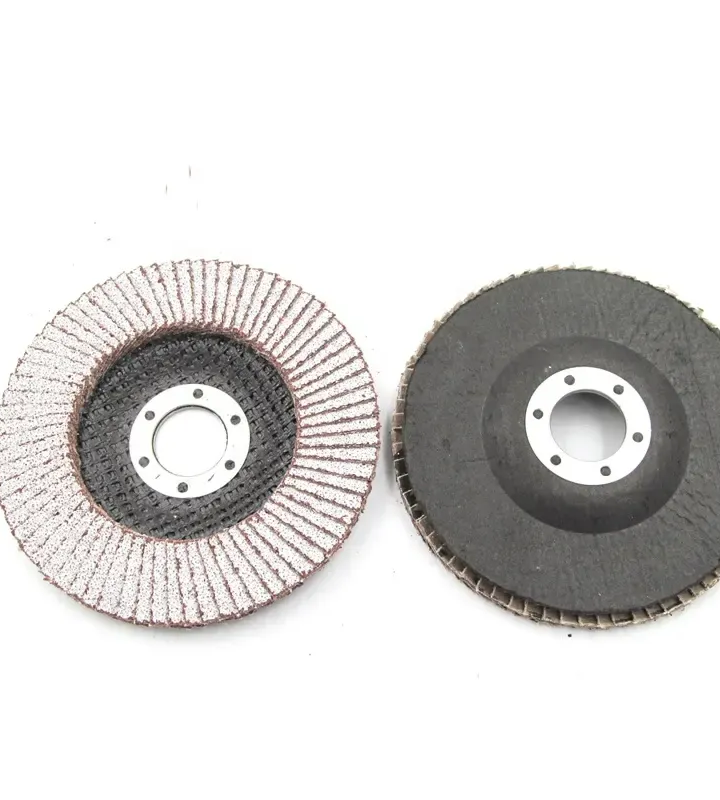

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Opt for high-speed aluminum oxide flap wheels designed for angle grinders, ensuring compatibility with curved surfaces and aggressive material removal. Our durable construction minimizes vibration, ideal for stainless steel, wood, or alloy polishing.

Ceramic abrasive grains in flap wheels offer extended lifespan and cooler grinding, reducing workpiece burn. They excel in high-pressure tasks like weld blending or deburring hardened metals, outperforming traditional aluminum oxide options.

Yes, compact shank-mounted flap wheels (e.g., 1/4" shaft) provide controlled polishing in tight spaces. Pair with fine-grit non-woven abrasives for smooth finishes on automotive parts, molds, or intricate metalwork.

Electroplated diamond flap wheels deliver unmatched durability on ceramics, stone, or glass. Their consistent cutting action avoids uneven wear, making them cost-effective for industrial stone shaping or concrete surface prep.

Absolutely. Low-density non-woven flap wheels gently clean and finish soft metals or plastics without scratching. Use with lighter pressure for paint stripping, rust removal, or final satin finishes on sensitive substrates.

Multi-layered aluminum oxide abrasive flaps balance affordability and performance, ideal for general-purpose grinding. They resist loading during woodworking or metal fabrication, reducing downtime for wheel changes.